Our Process & Services

-

IOT for Production Line

We are dedicated in revolutionizing the manufacturing industry for latex products by implementing cutting-edge IoT solutions. Our primary focus is on developing innovative approaches that enable seamless data collection and utilization from equipment, leading to the identification and reduction of inefficiencies while enhancing industrial operations.

Through our initiatives, we aim to harness the power of IoT technology to gather valuable data from manufacturing lines and assembly robots. This data will be transferred to the Cloud, where we will employ advanced techniques to structure performance metrics specific to equipment and processes. By analyzing these metrics, we can gain insights into the overall effectiveness of operations, unveiling opportunities for innovation and improvement.

Moreover, our advanced systems allow us to monitor the manufacturing process closely, enabling us to identify equipment and process deficiencies, production gaps, and product defects. This comprehensive analysis helps us optimize manufacturing operations by pinpointing areas that require attention and implementing effective solutions.

To further enhance our capabilities, we will leverage AI-enabled IoT solutions. By incorporating artificial intelligence into our systems, we can create intelligent machines capable of simulating smart behavior. These AI-powered systems greatly reduce the need for human intervention and assist in decision-making processes.

At Inspire Impact, we are committed to driving positive change in the manufacturing industry by deploying IoT solutions that streamline data collection, optimize operations, and foster innovation.

-

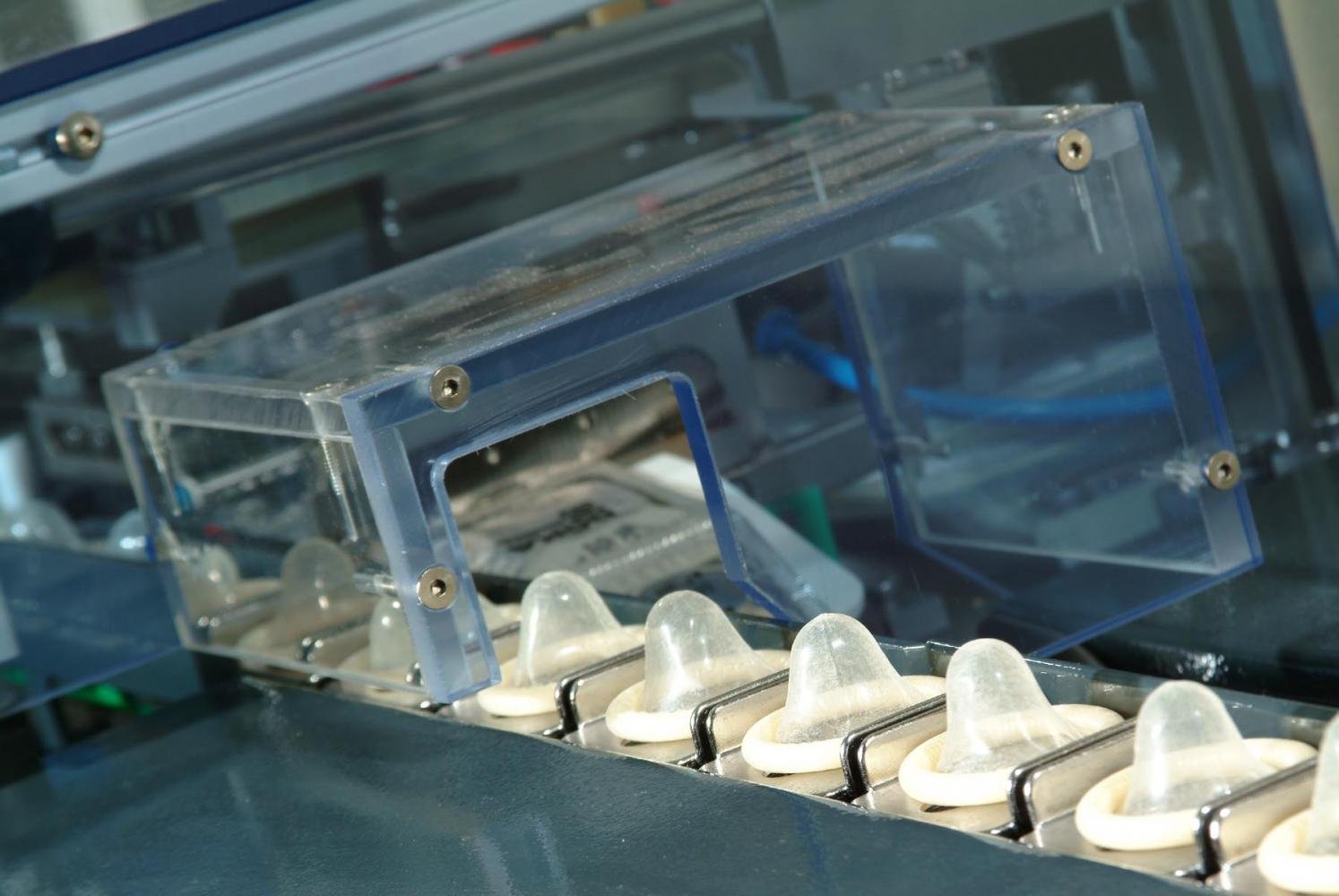

Dipping

The process of immersing qualified latex using a machine equipped with a molded glass rod is known as dipping. Condoms undergo a dipping process, whereby the duration of dipping determines the thickness of the condom.

-

Washing & Drying

The process of immersing qualified latex using a machine equipped with a molded glass rod is known as dipping. Condoms undergo a dipping process, whereby the duration of dipping determines the thickness of the condom.

-

Visual Inspection & Testing

At our facility, we conduct a thorough quality check of our condoms. Our highly trained staff meticulously examines each product, checking for any defects such as leaks, inconsistencies in color or texture, and irregular edges. To ensure compliance with international standards, we employ a capacitive hole tester during our testing process.

-

Customized Ceiling & Packaging

In our packaging process, we utilize both manual labor and automated machines to package the products into foil and boxes.

Latex Condoms Lubricant Varieties

With Custom Flavored Lubricants

With Neutral Lubricants

Without Lubricants

Latex Condoms Size Varieties

Custom Size

Regular Fit

Large

Extra Large

Latex Condoms Texture Varieties

Custom Texture

Ribbed

Dotted

Ultra Thin